Phase field models

A phase field model is a mathematical model for solving interfacial problems. It has mainly been applied to solidification dynamics,[1] but it has also been applied to other situations such as viscous fingering,[2] fracture dynamics,[3] vesicle dynamics,[4] etc.

The method substitutes boundary conditions at the interface by a partial differential equation for the evolution of an auxiliary field (the phase field) that takes the role of an order parameter. This phase field takes two distinct values (for instance +1 and −1) in each of the phases, with a smooth change between both values in the zone around the interface, which is then diffuse with a finite width. A discrete location of the interface may be defined as the collection of all points where the phase field takes a certain value (e.g., 0).

A phase field model is usually constructed in such a way that in the limit of an infinitesimal interface width (the so-called sharp interface limit) the correct interfacial dynamics are recovered. This approach permits to solve the problem by integrating a set of partial differential equations for the whole system, thus avoiding the explicit treatment of the boundary conditions at the interface.

Phase field models were first introduced by Fix[5] and Langer,[6] and have experienced a growing interest in solidification and other areas.

Contents |

Equations of the Phase field model

Phase field models are usually constructed in order to reproduce a given interfacial dynamics. For instance, in solidification problems the front dynamics is given by a diffusion equation for either concentration or temperature in the bulk and some boundary conditions at the interface (a local equilibrium condition and a conservation law),[7] which constitutes the sharp interface model.

A number of formulations of the phase field model are based on a free energy functional depending on an order parameter (the phase field) and a diffusive field (variational formulations). Equations of the model are then obtained by using general relations of Statistical Physics. Such a functional is constructed from physical considerations, but contains a parameter or combination of parameters related to the interface width. Parameters of the model are then chosen by studying the limit of the model with this width going to zero, in such a way that one can identify this limit with the intended sharp interface model.

Other formulations start by writing directly the phase field equations, without referring to any thermodynamical functional (non-variational formulations). In this case the only reference is the sharp interface model, in the sense that it should be recovered when performing the small interface width limit of the phase field model.

Phase field equations in principle reproduce the interfacial dynamics when the interface width is small compared with the smallest length scale in the problem. In solidification this scale is the capillary length  , which is a microscopic scale. From a computational point of view integration of partial differential equations resolving such a small scale is prohibitive. However, Karma and Rappel introduced the thin interface limit,[8] which permitted to relax this condition and has opened the way to practical quantitative simulations with phase field models. With the increasing power of computers and the theoretical progress in phase field modelling, phase field models have become a useful tool for the numerical simulation of interfacial problems.

, which is a microscopic scale. From a computational point of view integration of partial differential equations resolving such a small scale is prohibitive. However, Karma and Rappel introduced the thin interface limit,[8] which permitted to relax this condition and has opened the way to practical quantitative simulations with phase field models. With the increasing power of computers and the theoretical progress in phase field modelling, phase field models have become a useful tool for the numerical simulation of interfacial problems.

Variational formulations

A model for a phase field can be constructed by physical arguments if one have an explicit expression for the free energy of the system. A simple example for solidification problems is the following:

![F[e,\phi]=\int d{\mathbf r} \left[ K|{\mathbf

\nabla}\phi|^2 %2B h_0f(\phi) %2B e_0u^2 \right]](/2012-wikipedia_en_all_nopic_01_2012/I/5f171d120a148623eb8a9efcfbee0b5d.png)

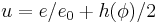

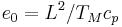

where  is the phase field,

is the phase field,  ,

,  is the local enthalpy per unit volume,

is the local enthalpy per unit volume,  is a certain polynomial function of

is a certain polynomial function of  , and

, and  (where

(where  is the latent heat,

is the latent heat,  is the melting temperature, and

is the melting temperature, and  is the specific heat). The term with

is the specific heat). The term with  corresponds to the interfacial energy. The function

corresponds to the interfacial energy. The function  is usually taken as a double-well potential describing the free energy density of the bulk of each phase, which themselves correspond to the two minima of the function

is usually taken as a double-well potential describing the free energy density of the bulk of each phase, which themselves correspond to the two minima of the function  . The constants

. The constants  and

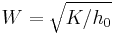

and  have respectively dimensions of energy per unit length and energy per unit volume. The interface width is then given by

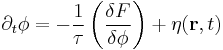

have respectively dimensions of energy per unit length and energy per unit volume. The interface width is then given by  . The phase field model can then be obtained from the following variational relations:[9]

. The phase field model can then be obtained from the following variational relations:[9]

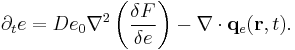

where D is a diffusion coefficient for the variable  , and

, and  and

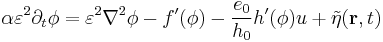

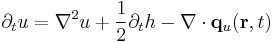

and  are stochastic terms accounting for thermal fluctuations (and whose statistical properties can be obtained from the fluctuation dissipation theorem). The first equation gives an equation for the evolution of the phase field, whereas the second one is a diffusion equation, which usually is rewritten for the temperature or for the concentration (in the case of an alloy). These equations are, scaling space with

are stochastic terms accounting for thermal fluctuations (and whose statistical properties can be obtained from the fluctuation dissipation theorem). The first equation gives an equation for the evolution of the phase field, whereas the second one is a diffusion equation, which usually is rewritten for the temperature or for the concentration (in the case of an alloy). These equations are, scaling space with  and times with

and times with  :

:

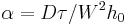

where  is the nondimensional interface width,

is the nondimensional interface width,  , and

, and  ,

,  are nondimensionalized noises.

are nondimensionalized noises.

Alternative Energy Density Functions

The choice of free energy function,  , can have a signficant effect on the physical behaviour of the interface, and should be selected with care. The double-well function represents an approximation of the Van der Waals EOS near the critical point, and has historically been used for its simplicity of implementation when the phase field model is employed solely for interface tracking purposes. However, this has led to the frequently observed spontaneous drop shrinkage phenomenon, whereby the high phase miscibility predicted by an Equation of State near the critical point allows significant interpenetration of the phases and can eventually lead to the complete disappearance of a droplet whose radius is below some critical value.[10] Minimizing perceived continuity losses over the duration of a simulation requires limits on the Mobility parameter, resulting in a delicate balance between interfacial smearing due to convection, interfacial reconstruction due to free energy minimization (i.e. mobility-based diffusion), and phase interpenetration, also dependent on the mobility. A recent review of alternative energy density functions for interface tracking applications has proposed a modified form of the double-obsticle function which avoids the spontaneous drop shrinkage phenomena and limits on mobility,[11] with comparative results provide for a number of benchmark simulations using the double-well function and the VOF sharp interface technique. The proposed implementation has a computational complexity only slightly greater than that of the double-well function, and may prove useful for interface tracking applications of the phase field model where the duration/nature of the simulated phenomena introduces phase continuity concerns (i.e. small droplets, extended simulations, multiple interfaces, etc.).

, can have a signficant effect on the physical behaviour of the interface, and should be selected with care. The double-well function represents an approximation of the Van der Waals EOS near the critical point, and has historically been used for its simplicity of implementation when the phase field model is employed solely for interface tracking purposes. However, this has led to the frequently observed spontaneous drop shrinkage phenomenon, whereby the high phase miscibility predicted by an Equation of State near the critical point allows significant interpenetration of the phases and can eventually lead to the complete disappearance of a droplet whose radius is below some critical value.[10] Minimizing perceived continuity losses over the duration of a simulation requires limits on the Mobility parameter, resulting in a delicate balance between interfacial smearing due to convection, interfacial reconstruction due to free energy minimization (i.e. mobility-based diffusion), and phase interpenetration, also dependent on the mobility. A recent review of alternative energy density functions for interface tracking applications has proposed a modified form of the double-obsticle function which avoids the spontaneous drop shrinkage phenomena and limits on mobility,[11] with comparative results provide for a number of benchmark simulations using the double-well function and the VOF sharp interface technique. The proposed implementation has a computational complexity only slightly greater than that of the double-well function, and may prove useful for interface tracking applications of the phase field model where the duration/nature of the simulated phenomena introduces phase continuity concerns (i.e. small droplets, extended simulations, multiple interfaces, etc.).

Sharp interface limit of the Phase field equations

A phase field model can be constructed to purposely reproduce a given interfacial dynamics as represented by a sharp interface model. In such a case the sharp interface limit (i.e. the limit when the interface width goes to zero) of the proposed set of phase field equations should be performed. This limit is usually taken by asymptotic expansions of the fields of the model in powers of the interface width  . These expansions are performed both in the interfacial region (inner expansion) and in the bulk (outer expansion), and then are asymptotically matched order by order. The result gives a partial differential equation for the diffusive field and a series of boundary conditions at the interface, which should correspond to the sharp interface model and whose comparison with it provides the values of the parameters of the phase field model.

. These expansions are performed both in the interfacial region (inner expansion) and in the bulk (outer expansion), and then are asymptotically matched order by order. The result gives a partial differential equation for the diffusive field and a series of boundary conditions at the interface, which should correspond to the sharp interface model and whose comparison with it provides the values of the parameters of the phase field model.

Whereas such expansions were in early phase field models performed up to the lower order in  only, more recent models use higher order asymptotics (thin interface limits) in order to cancel undesired spureous effects or to include new physics in the model. For example, this technique has permitted to cancel kinetic effects,[8] to treat cases with unequal diffusivities in the phases,[12] to model viscous fingering[2] and two-phase Navier–Stokes flows,[13] to include fluctuations in the model,[14] etc.

only, more recent models use higher order asymptotics (thin interface limits) in order to cancel undesired spureous effects or to include new physics in the model. For example, this technique has permitted to cancel kinetic effects,[8] to treat cases with unequal diffusivities in the phases,[12] to model viscous fingering[2] and two-phase Navier–Stokes flows,[13] to include fluctuations in the model,[14] etc.

Multi Phase Field Models

In multi a phase field model microstructure is described by set of order parameters each one is related to a specific phase or crystallographic orientation. This model is mostly used for solid state phase transformations where multiple grains evolve (e.g. grain growth, recrystallization or first order transformation like austenite to ferrite in ferrous alloys. Besides allowing the description of multiple grains in a microstructure Multi Phase Field models especially allow for consideration of multiple thermodynamic phases as occurring e.g. in technical alloy grades.[15]

Software

- The Mesoscale Microstructure Simulation Project (MMSP) is a collection of c++ classes for grid-based microstructure simulation.

- The Microstructure Evolution Simulation Software (MICRESS) is a multi-phase field simulation package developed at RWTH-Aachen.

Further reading

- R. Gonzalez-Cinca et al., in Advances in Condensed Matter and Statistical Mechanics, ed. by E. Korucheva and R. Cuerno, Nova Science Publishers (2004) a review on phase field models.

- L-Q Chen, Annual Review of Materials Research, Vol. 32: 113-140 (2002) Phase field models in solidification

- N. Moelans, B. Blanpain, P.Wollants, Calphad, Vol. 32: 268-294 (2008) An introduction to phase-field modeling for microstructure evolution

- I. Steinbach:Phase-field models in Materials Science –Topical Review, Modelling Simul. Mater. Sci. Eng. 17 (2009)073001

- S.G.Fries, B.Böttger, J.Eiken,I.Steinbach:Upgrading CALPHAD to microstructure simulation: the phase-field method, Int.J.Mat.Res 100(2009)2

- R. Qin and H. K. D. H. Bhadeshia, a critical assessment of the phase field method, 2010, published in Materials Science and Technology.

- A.A. Donaldson et al., Diffuse interface tracking of immiscible fluids: Improving phase continuity through free energy density selection, 2011, published in the International Journal of Multiphase Flow.

References

- ^ WJ. Boettinger et al. Annual Review of Materials Research Vol. 32: 163-194 (2002)

- ^ a b R. Folch et al. Phys. Rev. E 60, 1734 - 1740 (1999)

- ^ A. Karma et al. Phys. Rev. Lett. 87, 045501 (2001)

- ^ T. Biben et al. Phys. Rev. E 72, 041921 (2005)

- ^ G.J. Fix, in Free Boundary Problems: Theory and Applications, Ed. A. Fasano and M. Primicerio, p. 580, Pitman (Boston, 1983).

- ^ J.S. Langer, Models of pattern formation in first–order phase transitions, in Directions in Condensed Matter Physics p. 165, Ed. G. Grinstein and G. Mazenko, World Scientific, Singapore, (1986).

- ^ J.S. Langer, Rev. Mod. Phys. 52, 1 (1980)

- ^ a b A. Karma and W.J. Rappel Phys. Rev. E 57, 4323 - 4349 (1998)

- ^ P.C. Hohenberg and B.I. Halperin, Rev. Mod. Phys. 49, 435 (1977)

- ^ [Yue, P., Zhou, C., Feng, J.J., 2007. Spontaneous shrinkage of drops and mass conservation in phase-field simulations. J. Comp. Phys. 223, 1–9.]

- ^ A.A. Donaldson et al., IJMF 37, 777-787, 2011

- ^ G. B. McFadden et al., Physica D 144, 154-168 (2000)

- ^ D. Jacqmin, J. Comput. Phys. 155,96-127 (1999)

- ^ R. Benítez and L. Ramírez-Piscina Phys. Rev. E 71, 061603 (2005)

- ^ Schmitz, G. J.; Böttger, B., Eiken, J., Apel ,M., Viardin, A., Carré ,A. and Laschet,G.. (2011). "Phase-field based simulation of microstructure evolution in technical alloy grades". Int J Adv Eng Sci Appl Math. doi:10.1007/s12572-011-0026-y.